Explore our boiler blog for expert insights, industry updates, and valuable tips on boiler maintenance, efficiency, and more.

Explore our boiler blog for expert insights, industry updates, and valuable tips on boiler maintenance, efficiency, and more.

Steam boilers are essential in both industrial and commercial operations. They provide reliable heat and steam for manufacturing, power generation, and building heating systems. However, when a steam boiler problem occurs, it can lead to costly downtime, energy waste, and safety risks. Understanding how to identify, troubleshoot, and fix common issues is crucial to maintaining system performance and efficiency.

In this comprehensive guide, we walk through the most frequent steam boiler troubleshooting issues, their causes, and expert-recommended solutions to keep your system running smoothly.

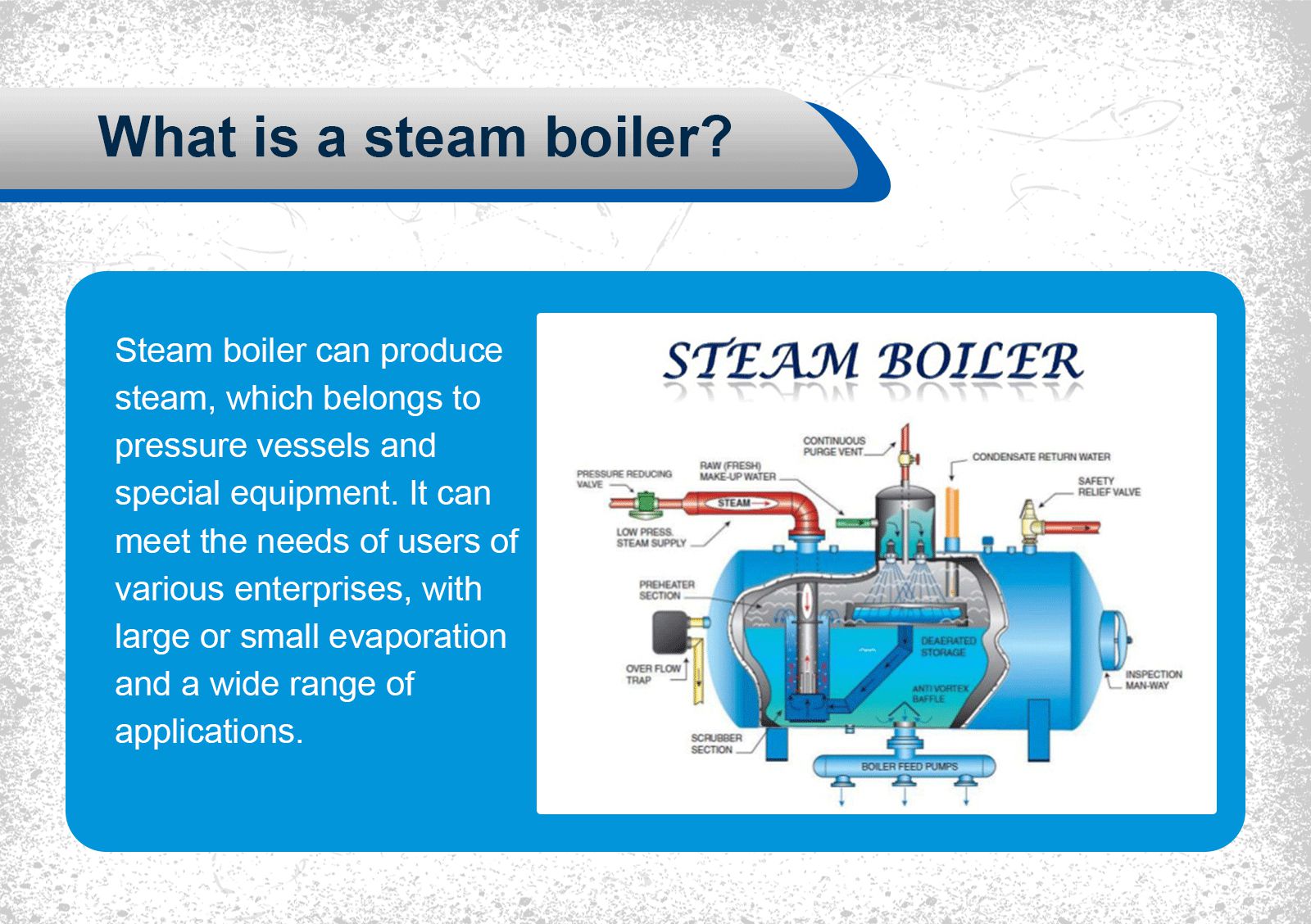

Before diving into troubleshooting, it’s important to understand how a steam boiler operates.

A typical steam boiler heats water in a closed vessel until it turns into steam. The generated steam is distributed through pipes to provide heating or power for various applications. Key components include:

When any of these components malfunction, it can lead to reduced efficiency or complete system failure.

Symptoms: No steam output or insufficient heating.

Possible Causes: Ignition failure or burner malfunction, faulty thermostat or pressure switch, low water levels preventing heat transfer.

Symptoms: Inconsistent steam output or system shutdown.

Possible Causes: Leaking valves or pipes, air trapped in the system, faulty pressure relief valve.

Symptoms: Unusual sounds during operation.

Possible Causes: Kettling caused by limescale buildup, air in the heating system, uneven water flow or temperature fluctuations.

Symptoms: Water pooling near the boiler or visible drips.

Possible Causes: Corroded pipes or joints, worn gaskets or seals, cracks in the heat exchanger.

Symptoms: Frequent cycling or automatic shutdowns.

Possible Causes: Faulty sensors or control board, overheating or low-water cut-off triggered, poor ventilation or blocked flue.

Ensure the boiler is receiving adequate electricity, gas, or oil. Inspect switches, circuit breakers, isolation valves, and fuel pressure.

Low water levels can trigger automatic shutdowns. Refill the system per manufacturer guidelines and inspect for leaks at valves, joints, and the feedwater line.

Normal steam boiler pressure often ranges from 10–15 psi (system dependent). If the reading is low, check for leaks, faulty pressure controls, or a failing relief valve.

Air trapped in pipes can cause noise and poor heat distribution. Bleed radiators or use air vents to release trapped air safely.

If the boiler isn’t heating, the burner may be dirty or misaligned, or the pilot flame may be out. Clean components and re-establish ignition according to safety procedures.

Modern boilers display error codes on their control panels. Consult the manual to identify and address the specific issue.

Verify thermostats, pressure switches, and limit controls are functioning correctly. Replace faulty sensors to prevent overheating or nuisance shutdowns.

Effective steam boiler troubleshooting not only prevents downtime but also improves energy efficiency. Consider these upgrades for long-term savings:

While minor checks can be performed in-house, call a qualified boiler technician if you encounter:

A well-maintained steam boiler is the heart of efficient, safe operations. By understanding common steam boiler problems, following a structured steam boiler troubleshooting process, and applying preventive maintenance, you can minimize downtime and maximize efficiency. Whether your issue is low boiler pressure, unusual noises, or a boiler not heating, a disciplined approach ensures reliable performance and lower operating costs.

We have more than 20 years of experience in boiler system equipment research and development and manufacturing. And committed to designing and producing boilers that suit your needs, including fire-tube, water-tube, and steam boilers, while also staying up-to-date with the latest technological boiler.

Get in touch