Explore our boiler blog for expert insights, industry updates, and valuable tips on boiler maintenance, efficiency, and more.

Explore our boiler blog for expert insights, industry updates, and valuable tips on boiler maintenance, efficiency, and more.

When choosing an industrial boiler system, one of the key decisions is whether to use a gas fired boiler or a coal fired boiler. Both systems are widely used in industrial sectors such as power generation, chemical processing, textile manufacturing, and food production. However, they differ significantly in terms of cost, efficiency, environmental impact, and maintenance. This article compares gas and coal boilers from multiple perspectives to help you make the right investment for your plant.

Gas fired boilers use natural gas, LPG, or biogas as fuel. They are known for clean combustion, high automation, and lower emissions.

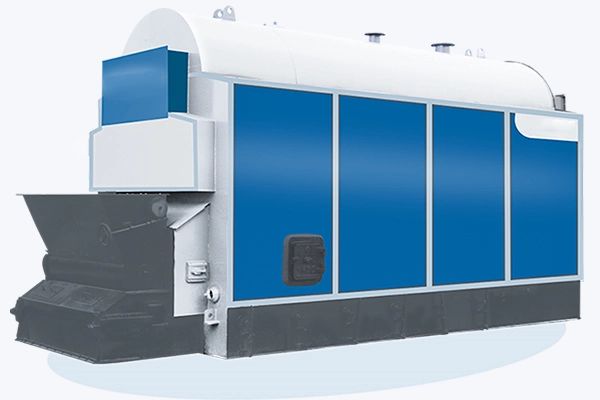

Coal fired boilers, on the other hand, use solid coal as fuel — often cheaper but dirtier — and require more complex operation and maintenance.

| Feature | Gas Fired Boiler | Coal Fired Boiler |

|---|---|---|

| Fuel Type | Natural gas, LPG, biogas | Bituminous or anthracite coal |

| Combustion Efficiency | 90%–98% | 75%–85% |

| Automation Level | High | Medium to low |

| Operation | Easy and stable | Requires manual handling |

| Environmental Impact | Low emissions | High CO₂ and dust output |

The initial investment for a gas boiler is generally higher because of burner systems and automation components. However, its operating cost is often lower due to better combustion efficiency and less maintenance.

| Cost Aspect | Gas Fired Boiler | Coal Fired Boiler |

|---|---|---|

| Initial Price | 10–20% higher | Lower equipment cost |

| Fuel Price (per MMBtu) | $8–12 | $3–5 |

| Maintenance Cost | Low | High |

| Installation | Simple (requires gas pipeline) | Complex (fuel storage and ash system) |

| Total Lifetime Cost | Moderate | Often higher due to maintenance |

Although coal is cheaper per ton, its handling, storage, and emission control systems increase total cost over time. In addition, carbon taxes in many regions make gas systems more cost-effective in the long run.

Gas fired boilers achieve higher thermal efficiency because combustion can be precisely controlled. Coal fired boilers have lower efficiency due to uneven fuel quality and manual operation.

This difference can lead to fuel savings of 10–20% annually, especially in continuous production industries such as textiles and food processing.

Environmental standards are becoming stricter worldwide. Gas fired boilers emit less CO₂, SO₂, and particulate matter, making them easier to comply with local emission regulations. Coal systems, even with advanced filters, produce more pollutants and require costly desulfurization and dust removal equipment.

| Environmental Factor | Gas Boiler | Coal Boiler |

|---|---|---|

| CO₂ Emissions | Low | High |

| SO₂ Emissions | Minimal | Significant |

| Particulate Emissions | Negligible | High (requires bag filters) |

| Carbon Tax Impact | Lower | Higher |

| Permit and Compliance | Easy to obtain | Increasingly restricted |

Example: In regions like the EU and Southeast Asia, several manufacturing parks are replacing coal boilers with gas-fired steam systems to meet carbon neutrality goals.

| Industry | Recommended System | Reason |

|---|---|---|

| Food & Beverage | Gas Fired Boiler | Clean combustion and stable steam quality |

| Textile & Dyeing | Gas Fired Boiler | High thermal control and efficiency |

| Cement & Power Generation | Coal Fired Boiler | High energy demand and cost sensitivity |

| Paper & Pulp | Gas Fired Boiler | Lower maintenance and cleaner exhaust |

| Chemical Processing | Gas Fired Boiler | Consistent heating and safety compliance |

Gas boilers are designed for automatic ignition, modulation, and shutoff, which reduces manual labor. Coal boilers require frequent ash removal, slag handling, and fuel feeding, leading to higher downtime and labor costs.

Maintenance Insights:

Over time, the difference in operation convenience can significantly affect productivity and maintenance budgets.

The right choice depends on your industry, budget, fuel availability, and emission policy.

In most modern industries, gas boilers are gradually replacing coal systems due to their efficiency and environmental benefits. For companies planning to upgrade their energy infrastructure, investing in a gas fired boiler system is a future-proof decision.

Tip: If your factory is planning an energy system upgrade, consider hybrid or dual-fuel systems that allow switching between gas and biomass — combining cost efficiency with sustainability. WhatsApp: +8613838529852

We have more than 20 years of experience in boiler system equipment research and development and manufacturing. And committed to designing and producing boilers that suit your needs, including fire-tube, water-tube, and steam boilers, while also staying up-to-date with the latest technological boiler.

Get in touch