Explore our boiler blog for expert insights, industry updates, and valuable tips on boiler maintenance, efficiency, and more.

Explore our boiler blog for expert insights, industry updates, and valuable tips on boiler maintenance, efficiency, and more.

A steam boiler is an essential device in many industrial applications. It converts the energy of fuel into heat, which produces steam for power generation, manufacturing, and process heating. Understanding the main parts of a steam boiler and how they work helps operators improve efficiency and reduce maintenance costs.

The working principle of a steam boiler is simple. The boiler burns fuel such as gas, oil, or biomass to produce heat. This heat is transferred to water, turning it into steam. The steam is then used to drive turbines or support industrial processes. Every component in the system plays a specific role to make this process efficient and safe.

The boiler shell is the outer cylindrical body that contains water and steam under pressure. It acts as a pressure vessel and ensures that the generated steam is safely stored and delivered when needed.

The furnace is where fuel combustion takes place. Efficient combustion depends on good air supply and proper burner design. A well-designed furnace improves heat transfer and reduces unburned fuel, lowering operating costs.

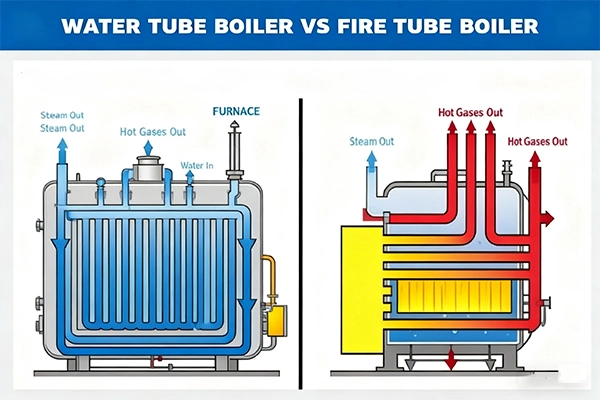

In a fire tube boiler, hot gases pass through tubes surrounded by water. In a water tube boiler, water flows inside tubes heated by external gas flames. Water tube boilers are usually more efficient and suitable for high-pressure operations.

The boiler burner is a vital component that controls the fuel - air mixture and the ignition process. It ensures that the fuel is burned at the right speed and under the right conditions. Modern burners are highly advanced, featuring things like variable speed controls and advanced ignition systems. For instance, a modulating burner can adjust the fuel flow based on the steam demand, which helps save energy. A malfunctioning burner can cause problems such as uneven heating, high emissions, and increased fuel consumption.

The superheater increases the temperature of steam above its saturation point. This improves the energy content of the steam and boosts the efficiency of turbines or other process equipment.

Maintaining the proper water level in the boiler is essential for safe and efficient operation. The water level controller monitors the water level and regulates the water supply to the boiler. If the water level is too low, it can cause overheating and damage to the boiler tubes. Conversely, if the water level is too high, it can lead to water being carried over into the steam system, which can damage downstream equipment. A reliable water level controller can prevent these issues and ensure the smooth running of the boiler.

The air preheater recovers heat from the flue gases to warm the combustion air. Hotter air leads to better fuel burning and reduced emission levels. This small part provides a big efficiency gain.

Safety valves release excess pressure to protect the boiler. Pressure and temperature gauges allow operators to monitor system conditions. Modern PLC control systems automate boiler operations and ensure stable, efficient performance with fewer manual errors.

Each part of a boiler contributes to overall performance. Clean heat exchange surfaces ensure better heat transfer. The economizer and air preheater recover energy that would otherwise be lost. Automation and continuous monitoring help maintain ideal combustion conditions and reduce wasted fuel.

Maintenance costs can be minimized by improving operational control and selecting durable components. Use automatic blowdown systems to remove impurities. Install continuous feedwater control to maintain the right water level. Choose corrosion-resistant materials and trusted suppliers to extend service life.

Predictive maintenance also helps reduce downtime. Using temperature and pressure sensors, operators can detect problems early before major damage occurs.

Old boilers can benefit from modern upgrades. Installing a high-efficiency burner reduces fuel use. Adding an economizer or air preheater captures more heat from flue gases. Replacing manual controls with PLC or IoT systems improves monitoring, safety, and energy efficiency.

Every part of a steam boiler plays a key role in its performance. Understanding the function of each component helps operators make better decisions about maintenance and efficiency. By using high-quality parts, keeping the system clean, and upgrading critical components, you can reduce fuel costs and extend boiler life.

A well-maintained boiler not only saves money but also supports cleaner, safer, and more sustainable industrial production.

Looking to improve your steam boiler efficiency or upgrade key parts? Contact us for professional advice, replacement parts, and customized boiler solutions that enhance performance and reduce long-term costs. WhatsApp: +8613838529852

We have more than 20 years of experience in boiler system equipment research and development and manufacturing. And committed to designing and producing boilers that suit your needs, including fire-tube, water-tube, and steam boilers, while also staying up-to-date with the latest technological boiler.

Get in touch